As a hybrid inverter of PV + energy storage + diesel generation, in order to keep the PV power generation efficiency at the highest level, MPS needs to follow two configuration principles (boost mode and buck mode) when configuring.

When should I choose buck configuration mode?

When should I choose the boost configuration mode?

MPS Buck-Boost Mode Related FAQs

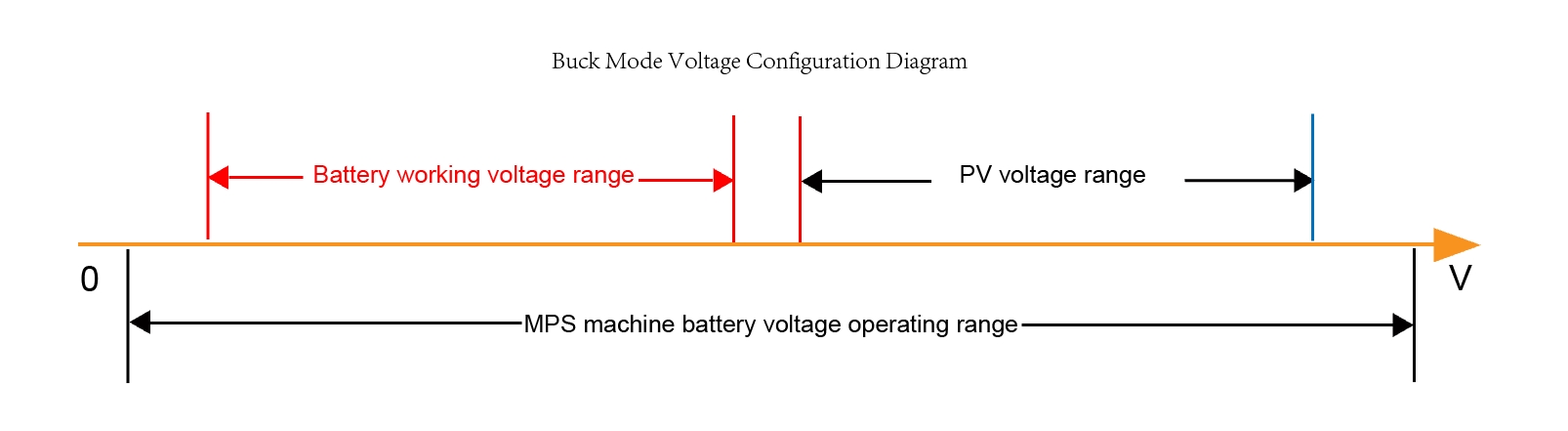

At the project application site, the working voltage of the photovoltaic module at extreme high temperature > the maximum working voltage of the battery;

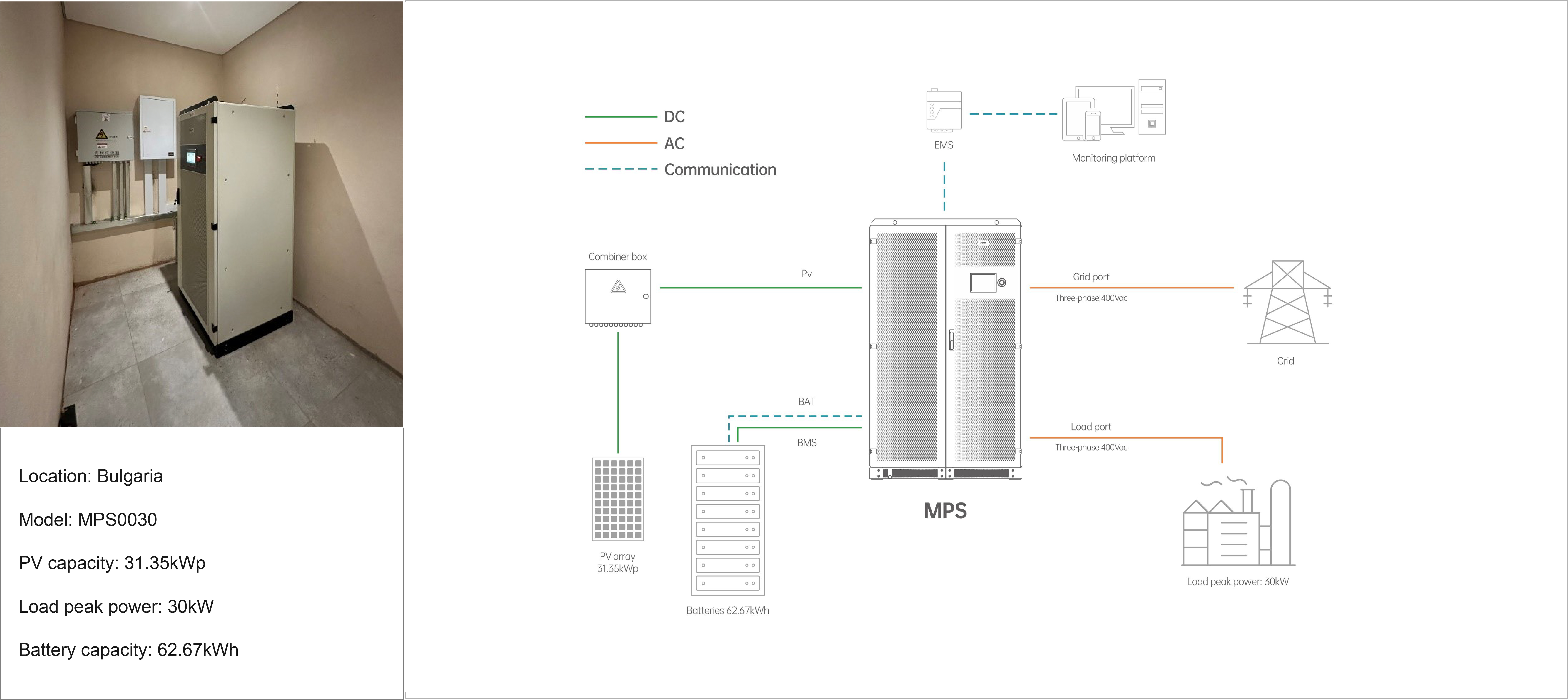

For example 1:Buck Mode

PV configuration table | |

|---|---|

Number of Solar Panel | 57 pcs |

Power Output of Each PV Panel | 550 Wp |

Actual Installed PV Capacity | 31.35 kWp |

Open Circuit Voltage-Voc(25°C) | 37.5 V |

Max. Power Voltage-V(Mpp) | 31.2 V |

Temp. Coefficient of P(MAX) | -0.34%/°C |

Temp. Coefficient of Voc | -0.25%/°C |

PV Panel Configuration | 19S3P |

Local Temp. Range | -15~40℃ |

Battery configuration table | |

Battery Type | LiFePO4 |

Number of Battery Packs | 12 |

Voltage of Each Battery Pack | 51.2V |

Capacity of Each Battery Pack | 102Ah |

Battery Configuration | 12S1P |

Rated Voltage of Battery | 307.2 V |

Battery Voltage Range | 268.8-350.4 V |

Total Battery Capacity | 62.6688 kWh |

PV string open circuit voltage (under extreme low temperature conditions) = 37.5*19+(25°C-(-15°C))*37.5*0.25%=783.75V

783.75V (under extreme low temperature conditions) <1000V (maximum PV input voltage)

PV working voltage(Under extreme high temperature conditions)=522.26V

PV working voltage 522.26V (under extreme high temperature conditions)>350.4V (highest battery voltage)

conclusion: The configuration of this project meets the buck mode configuration principle of the integrated optical storage machine,Through the buck mode, the PV input voltage is reduced so that the PV voltage and the battery voltage are consistent at the DC side of the hybrid inverter.

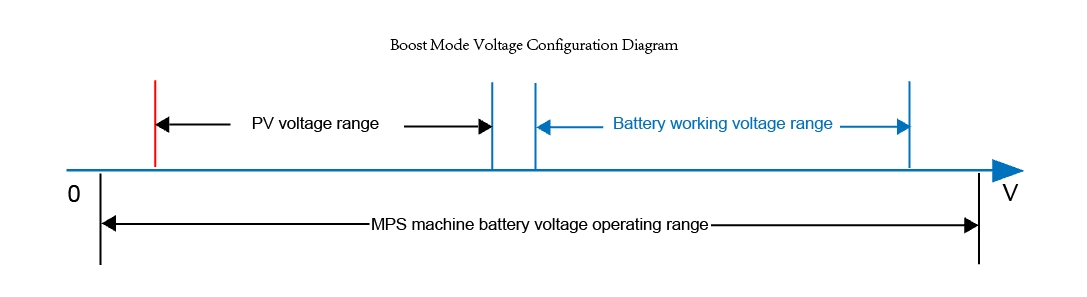

At the project application site, the open circuit voltage of the photovoltaic module at the extreme low temperature is ≤ the minimum operating voltage of the battery;

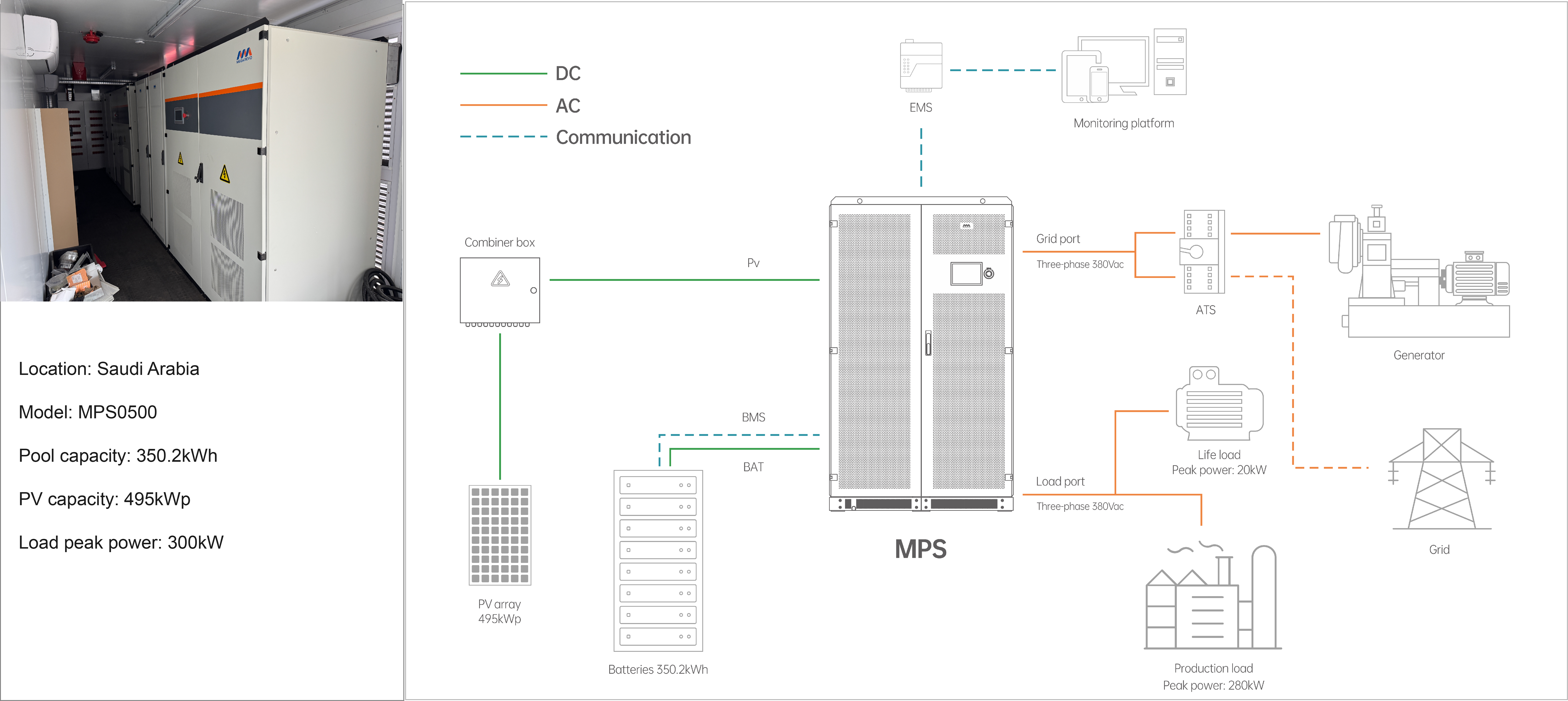

For example 2:Boost Mode

PV configuration table | |

|---|---|

Number of Solar Panel | 900 pcs |

Power Output of Each PV Panel | 550 Wp |

Actual Installed PV Capacity | 495 kWp |

Open Circuit Voltage-Voc(25°C) | 49.62 V |

Max. Power Voltage-V(Mpp) | 40.90 V |

Temp. Coefficient of P(MAX) | -0.35%/°C |

Temp. Coefficient of Voc | -0.28%/°C |

PV Panel Configuration | 12S75P |

Local Temp. Range | 5~50℃ |

Battery configuration table | |

Battery Type | LiFePO4 |

Number of Battery Packs | 38 |

Voltage of Each Battery Pack | 38.4V |

Capacity of Each Battery Pack | 240Ah |

Battery Configuration | 19S2P |

Rated Voltage of Battery | 729.6V |

Battery Voltage Range | 638.4-820.8 V |

Total Battery Capacity | 350.2 kWh |

PV string open circuit voltage (under extreme low temperature conditions) = 49.62*12+(25°C-5°C)*49.62*0.28%=628.78V

PV working voltage 628.78V (under extreme low temperature conditions) <1000V (maximum photovoltaic input voltage),And PV working voltage 628.78V<638.4V (minimum battery working voltage)

conclusion: The configuration of this project meets the MPS boost mode configuration principle. The boost mode is used to increase the photovoltaic input voltage to the same level as the battery voltage, and the DC side of the hybrid inverter is converged.

Yes, the buck-boost mode of MPS needs to be determined during the technical agreement stage. The wiring will be changed according to the buck-boost mode selection before leaving the factory. This buck-boost mode is determined by the hardware. (Although the buck-boost mode is determined at the factory, the buck-boost mode setting of the machine still needs to be set by the customer)

PV module specifications, battery configuration such as voltage range, capacity, and project application location (confirm altitude and temperature)

This affects the MPPT tracking efficiency, making it impossible for the photovoltaic system to work at the maximum power point, and even causing the photovoltaic system to be unable to charge the battery. The technical agreement review cannot be passed.

Currently the hardware supports it, but the software does not support it yet.

The number of photovoltaic panels (or capacity) connected to different MPPT modules can be different, but the voltage must be consistent. If the customer chooses two types of photovoltaic panels, the two types of photovoltaic panels need to be connected to different MPPT modules and the parameters of the two should be as consistent as possible.