The 1500V microgrid solution represents the cutting-edge trend in the development of medium-to-large-scale, high-reliability microgrids. It is not simply a voltage increase, but a systematic design and conceptual upgrade.

Below is a detailed analysis of the core content, advantages, challenges, and application scenarios of the 1500V microgrid solution.

Traditional microgrids typically have DC-side voltages of 400V, 630V, or 800V. A 1500V microgrid refers to a microgrid system that raises the DC-side voltage level to 1500V (usually referring to the maximum voltage, such as DC 1500V). This is primarily used in the DC coupling stages of photovoltaic arrays and energy storage batteries.

Key features:

• High DC voltage: Photovoltaic strings and energy storage battery clusters are connected in series to achieve higher DC voltages (e.g., 1000-1500V).

• System-level optimization: Involves a complete transformation across the entire chain from components and equipment to system design.

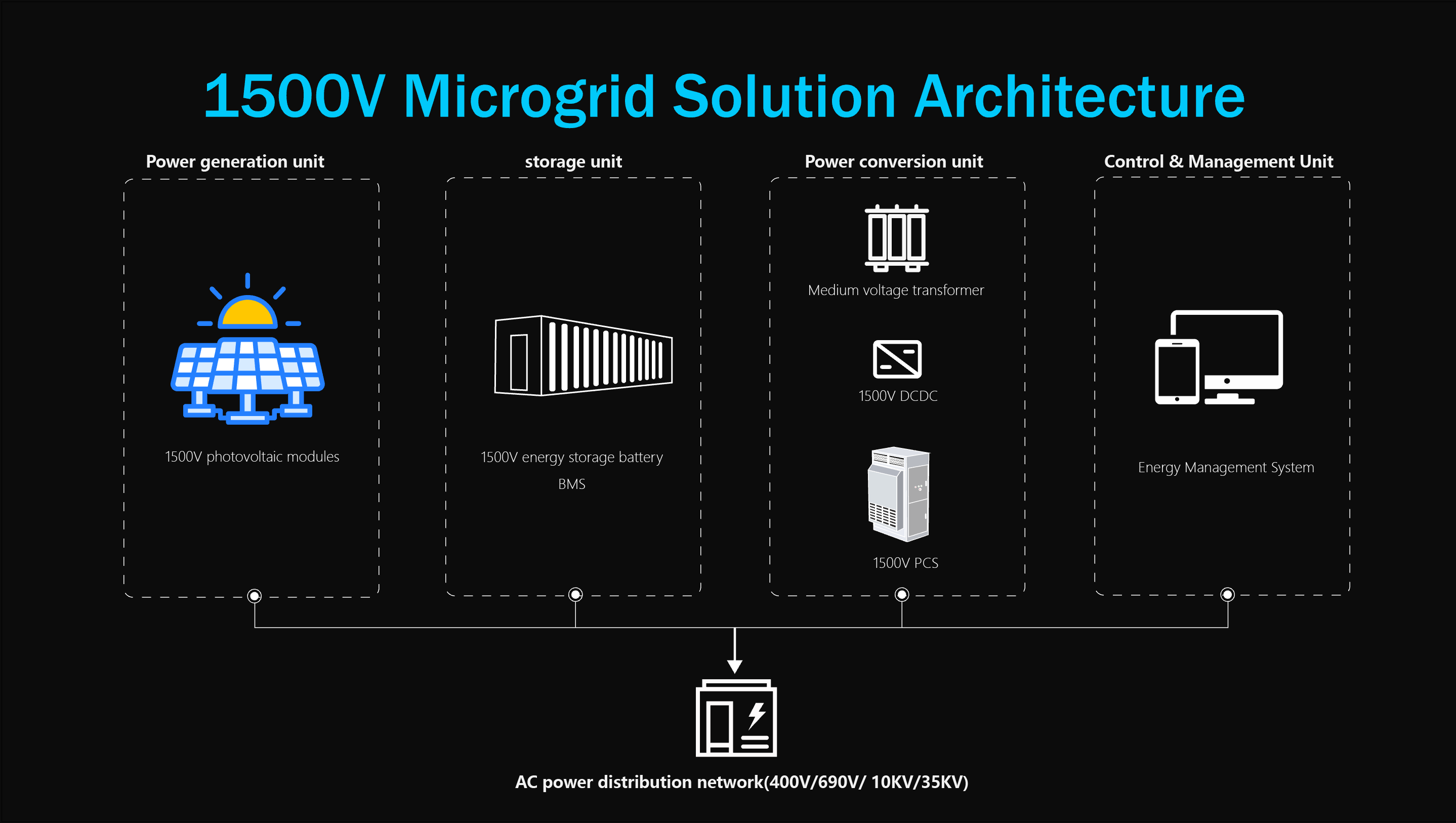

A typical 1500V photovoltaic-storage integrated microgrid mainly consists of the following components:

1. Significantly Reduced System Costs (BOS Costs):

Reduced Cable Losses: At the same power output, higher voltage results in lower current, allowing for smaller cable cross-sectional areas and saving up to 30%-40% on copper usage.

Reduced Equipment Quantity: Larger capacities are achieved with a single 1500V inverter and combiner box, reducing the required number of units and consequently lowering costs for installation, wiring, land acquisition, and support structures.

Improved Operation and Maintenance Efficiency: Fewer equipment points reduce inspection and maintenance workload.

2. Improved System Efficiency:

Reduced Transmission Losses: Significantly reduced DC-side line losses and power losses improve overall system efficiency by 1%-2% (for large systems, this translates to substantial power generation gains).

Optimized Inverter Efficiency: Higher operating voltages allow inverter power devices (such as IGBTs) to operate within their high-efficiency range.

3. Increased System Capacity and Power Density:

More photovoltaic modules can be connected per string (e.g., 32 or more), reducing the number of strings and optimizing layout.

More suitable for large-scale PV power plants (≥5MW) and large-scale energy storage systems (MWh level).

4.More suitable for integration with the DC side of high-voltage energy storage systems:

Modern lithium iron phosphate battery energy storage systems are developing towards 1500V high-voltage clusters. A 1500V microgrid enables efficient and seamless integration of photovoltaics and energy storage on the DC side, reducing conversion stages and improving response speed and overall energy efficiency.

1. Extremely High Safety Requirements:

Challenges: High voltage brings higher risks of electric arcing, insulation requirements, and personal safety risks. DC arcs are more difficult to extinguish.

Countermeasures:

Dedicated Equipment: Circuit breakers and disconnect switches with DC arc detection and interruption functions must be used.

Enhanced Insulation: The insulation class of components, cables, and connectors must meet 1500V standards (such as UL and IEC relevant standards).

Rigorous Design: More stringent electrical clearance and creepage distance designs.

Intelligent Protection: Equipped with more sensitive and faster protective relays and ground fault detection systems.

2. Industry Chain Maturity:

Challenge: Although it has become the mainstream trend, compared to systems below 1000V, the selection of brands and models for specialized equipment such as components, inverters, combiner boxes, and switches for 1500V is relatively limited, and prices may be slightly higher.

Solution:Choose leading suppliers with mature technology in the industry

3. Design and Maintenance Professionalism:

Challenge:Requires higher levels of professional knowledge and skills from system design, installation, and maintenance personnel.

Solution: Design, construction, and post-maintenance must be carried out by teams with extensive experience in high-voltage systems. Strengthen personnel training.

Large Industrial Park Microgrids: High energy load, abundant rooftop or open land resources, and a pursuit of high return on investment.

Data Center Microgrids: Extremely high requirements for power supply reliability and efficiency; 1500V systems can effectively reduce PUE.

Remote Area/Island Microgrids: Require large-scale photovoltaic-energy storage integration to reduce reliance on diesel generators; high-voltage systems can reduce long-distance transmission losses.

Large-Scale Integrated Photovoltaic-Energy Storage-Charging Stations: Integrate photovoltaics, large-capacity energy storage, and fast charging piles; the high-voltage DC bus can directly or via DC-DC converters supply power to the charging piles, resulting in a superior architecture.

Shared/Independent Energy Storage Power Stations: As a grid-side regulation resource, 1500V is currently the mainstream technology for large-scale energy storage systems.

1. Define Needs and Conduct Feasibility Analysis: Assess project scale (generally recommended >1MW), solar resources, load characteristics, and investment budget to confirm the economic advantages of the 1500V solution.

2. Select Reliable Technology Partners: Prioritize solution providers with extensive successful case studies and a complete product ecosystem in the 1500V photovoltaic-storage field.

3. Emphasize Safety Design: Prioritize safety from the system design stage, reserving sufficient protection redundancy.

4. Focus on Standards and Certifications: Ensure all critical equipment complies with the latest international (IEC 62548, UL 1741, etc.) and national/regional safety standards.

5. Plan for System Scalability: Consider the possibility of future interface expansion for photovoltaic capacity, energy storage capacity, or other energy sources (such as fuel cells) during the design phase.

the 1500V microgrid solution is a future-oriented, high-end technology choice focused on system-level cost reduction and efficiency improvement. It is particularly suitable for medium to large-scale photovoltaic-storage integration projects with stringent economic requirements. While pursuing profitability, the system's safety design and professional full lifecycle management must be prioritized.

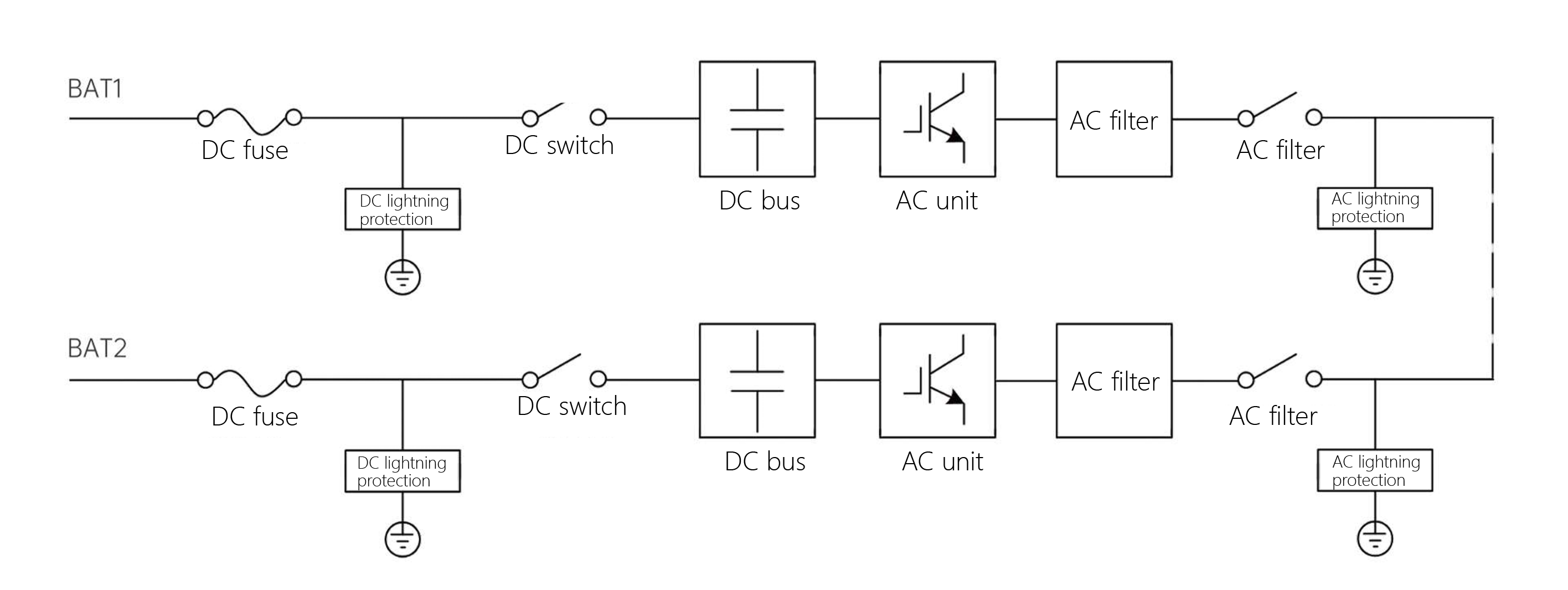

The Megarevo DC-side PCS employs three-level technology, achieving a maximum efficiency of 99.01%. It features IP66 protection for the entire unit and C3~C5 corrosion resistance options. It supports multiple operating modes including PQ, VF, and VSG, and is capable of grid-based deployment.

Smaller size and easier integration. Compatible with various energy storage media such as lithium batteries, sodium-ion batteries, flow batteries, hydrogen fuel cells, and supercapacitors.

Rated power (kW) | 2,400 | 2,750 | 3,150 | 2,500 | 3,450 |

DC voltage range (V) | 696~1,500 | 800~1,500 | 920~1,500 | 1,000~1,500 | 1,000~1,500 |

Max. DC current (A) | 1,935*2 | 1,935*2 | 1,935*2 | 1,402*2 | 1,402*2 |

Number of DC input circuits | 2 | 2 | 2 | 2 | 2 |

Rated power (kW) | 2,400 | 2,750 | 3,150 | 2,500 | 3,450 |

Grid type | 3W+PE | 3W+PE | 3W+PE | 3W+PE | 3W+PE |

Isolation method | No isolation | No isolation | No isolation | No isolation | No isolation |

Rated grid frequency (Hz) | 50 / 60 | 50 / 60 | 50 / 60 | 50 / 60 | 50 / 60 |

Total harmonic distortion of current | <3% (Rated power) | <3% (Rated power) | <3% (Rated power) | <3% (Rated power) | <3% (Rated power) |

Rated output voltage (V) | 480 | 550 | 630 | 690 | 690 |

Protection grade | IP66 | IP66 | IP66 | IP66 | IP66 |